JB-15 Micro Piling Tubes

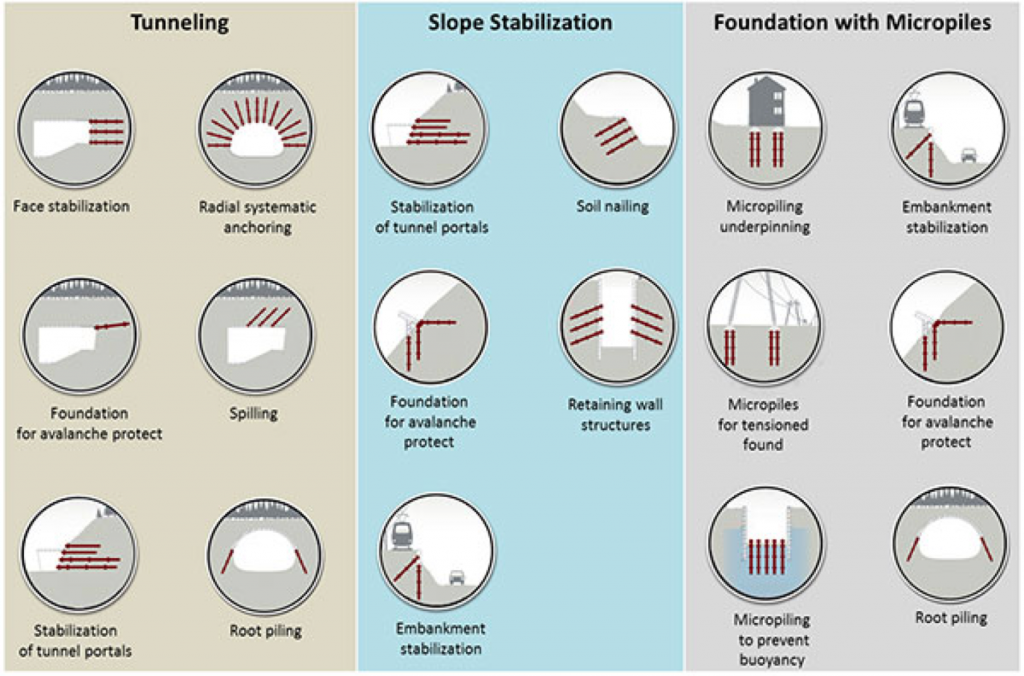

Micropiles are high performing, high capacity drilled deep foundation elements typically between 30mm-900mm in diameter that can extend to depths of 200 feet and achieve working loads of over 150 tons. Micropiles comprises of very strong steel casing, rebar and grout.

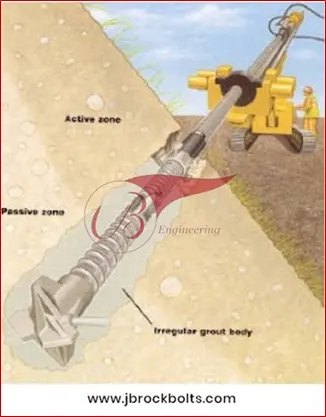

They transfer the structural load through improper soil layers to adaptable foundation soils. Commonly applied execution methods are drilling and driving with percussion or vibration, if necessary using ultra-compact equipment which permits working in tight spaces.

This means micropiles can also be installed within existing buildings. Micropiles are generally used when there are difficult ground conditions, such as natural or man-made obstructions, sensitive ground with adjacent structures, limited access/low headroom.

They are commonly used to replace deteriorating foundation systems, for the renovation of structures, and to support structures affected by adjacent construction.

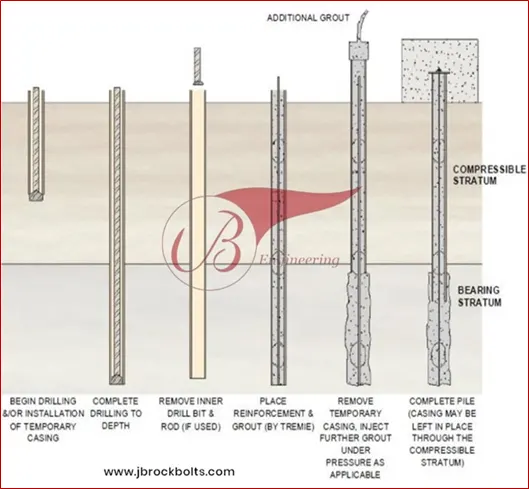

Micropile Process

This kind of deep foundation method includes small-diameter piles with diameters less than 15 inches. For the construction of micro piles, the ground is drilled using a temporary casing to stabilize the soil. After reaching the predetermined depth, the drill bit is removed, and the reinforcement and grout are placed inside the hole. We are shifting goods product by top rated packers and movers in Mohali. Finally, the temporary casing is removed, and additional grout is injected. In some cases, a permanent steel casing can be used in combination with the steel reinforcing member to provide additional lateral as well as axial capacity. The piling process is illustrated below.

Advantage of using a JB Engineering Micropile

Micropiles can resist relatively significant axial loads and moderate lateral loads. To improve their lateral load deficiency, they can be installed at any angle. This installation causes low disturbance to adjacent structures. However, they are vulnerable to buckling due to their being slender, and this issue should be considered in the design. This piling method’s installation equipment is relatively small and can be mobilized in limited areas and low headroom conditions.

Among the major foundation alternatives Surface conditions factor is the leading to the selection of micropiles.

The surface conditions include:

- Restricted headroom

- Restricted size of work zone

- Difficult access because of steep terrain where equipment could be lifted by crane and dropped into position, thus eliminating the need for an access road.

- Need to reduce environmental concerns (noise, vibration)

However, the cost of micropiles usually exceeds conventional piling systems and especially driven piles. Under certain combinations of circumstances, micro piles can be the cost-effective choice and sometimes the only feasible construction option.

Features and Capabilities of a Micropile:

- Quicker one-step installations.

- High load capacity as compared to other available stabilization systems.

- There is no need for a pre-drill of a hole for micropile installation because drilling and casing installation are done simultaneously.

- Provides greater densification for ground improvement with greater skin friction along the micropile depth.

- No disturbance to adjacent structures due to the installation of Micropiles.

JB Engineering Round & Square Bars Drilling Pipe

NAME: SOLID ROD BARS, SOLID AND HOLLOW BARS, DRILLING ROD BARS, DRILL STEM, HOLLOW THICK WALL THICKNESS PIPE, DRILLING PIPE JOINT, RAISE BORING DRILL PIPE.

SIZE: OD: 100-1000mm // ID: 5-240mm

RAW MATERIALS: Hot rolled, hot forged steel round bars

HEAT TREATMENT: Normalized; Annealed; Quenched and Tempered, pre-hardened.

SURFACE CONDITION: Oil anti-corrosive protection / black surface / peeling surface

JB Engineering Cold Drawn Seamless Steel Pipes

GRADE-2 TYPES: SOLID ROD BARS, SOLID AND HOLLOW BARS, DRILLING ROD BARS, DRILL STEM, HOLLOW THICK WALL THICKNESS PIPE, DRILLING PIPE JOINT, RAISE BORING DRILL PIPE.

SPECIFICATION: OD: 100-1000mm // ID: 5-240mm

TOLERANCE: Hot rolled, hot forged steel round bars

LENGTH: Normalized; Annealed; Quenched and Tempered, pre-hardened.

SURFACE: Oil anti-corrosive protection / black surface / peeling surface

APPLICATION: Machining parts, hydraulic cylinder, hydraulic pump, boiler, water/gas/fluid transportation etc.

ADVANTAGES: Compared with common hot rolled pipes, it can be of customized sizes. So accruing accurate sizes save both material and time.

JB Engineering Cold Rolled Precision Seamless Steel Pipe

SPECIFICATION: OD 5-200, ID 4-190MM

TOLERANCE: For both ID AND OD -0.05/+0.05mm

LENGTH: 4-12M Random length or as per request fixed length

SURFACE: Bright or dark / as per required

SPECIAL TEST: Crack/flaw detection, size tolerance inspection, flatting test, surface checking

APPLICATION:Boiler pipe, Hydraulic/Automobile pipe, Oil/Gas drilling, Machinery industry, mining, construction & decoration, Used on special purpose.

Other Varieties & Grades:

CARBON STEEL & STAINLESS STEEL

CARBON STEEL & STAINLESS STEEL: A333 Gr.3/Gr.6 etc.

ALLOY STEEL: ASTM A335 GR. P1/P5/P9/P11/P22/P91/P92 etc.

TYPES: Round, Square & Rectangular.

SIZE: 1/4" NB to 32" NB (Seamless) & 1/2" NB to 108" NB (Welded)